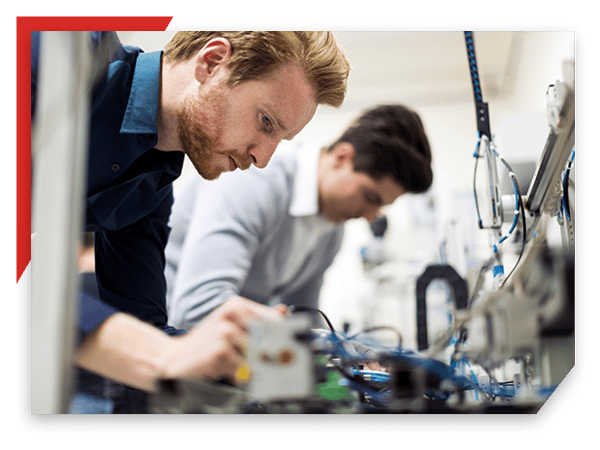

Qualification Testing Capabilities

Having access to on-site testing speeds production and delivery, which is important for customers seeking immediate solutions. Electromech’s on-site testing center allows our quality assurance team to perform most of the DO-160 Qualification tests on-site, which speeds delivery.

On-Site Testing Capabilities:

- Operating performance

- Life (continuous monitoring, digital controlled data acquisition)

- Shock and vibration (RTCA DO-160D and MIL-STD-810C)

- Temperature (-60º C to +174º C, DT = 10º C/min)

- Humidity (RTCA DO-160 and MIL-STD-810)

- Altitude (to 80,000 ft / 24.4 km)

- Small explosive decompression (bell jar to .1 micron vacuum/100,000 ft / 30.5 km in 2 min)

- Air flow to 6,000 f3/m (ASHRAE figure 12)

- EMI (electromagnetic interference) Emissions, Radiated and Conducted (RTCA DO-160 and MIL-STD-810)

Electromech Technologies partners with the National Institute for Aviation Research (NIAR) at Wichita State University for all other tests. NIAR, an unincorporated division of Wichita State University, is the most prominent academic aviation Research and Development institution in the United States, with global reach and expertise in research, development, testing, and certification.

Off-Site Testing Capabilities:

- Power Input and Voltage Spike (RTCA DO-160 and MIL-STD-810)

- Complete RTCA DO-160 and MIL-STD-810 testing